API 5L X65 Pipe and P11 Pipe Suppliers: Meeting Modern Industrial Demands with Strength and Reliability

In today’s fast-paced industrial environment, the demand for high-performance piping materials continues to grow across the oil & gas, petrochemical, power generation, and mechanical industries. Among the most widely trusted products in these sectors are the API 5L X65 Pipe and the pipes manufactured from ASME/ASTM grades such as P11. While both materials serve different purposes, they share a common reputation: exceptional strength, reliability, and suitability for critical applications. For industries looking to optimize performance and long-term durability, understanding these pipe types and selecting the right P11 pipe suppliers is essential.

Understanding API 5L X65 Pipe

The API 5L X65 Pipe is part of the API 5L specification, which covers seamless and welded steel pipes used primarily for the transportation of oil, natural gas, and water across vast distances. The X65 grade indicates a minimum yield strength of 65,300 psi, making it stronger than the commonly used X42 and X52 grades. This makes X65 the ideal choice for demanding pipeline environments where high pressure, temperature fluctuations, and corrosive elements are prevalent.

Key Features of API 5L X65 Pipe

1. High Strength and Durability

API 5L X65 Pipe offers exceptional mechanical strength, enabling it to withstand high stress and pressure conditions. This makes it suitable for offshore pipelines, deep-sea operations, and rugged terrain installations.

2. Excellent Weldability

Despite its high strength, the X65 grade maintains good weldability. Manufacturers can join pipes easily using conventional welding methods, allowing for seamless installation in large pipeline projects.

3. Superior Resistance to Corrosion

The material composition of API 5L X65 provides improved resistance to corrosive elements such as hydrogen sulfide (H₂S), carbon dioxide (CO₂), and saltwater. This ensures longer service life and lower maintenance requirements.

4. Versatile Applications

API 5L X65 Pipe is widely used in:

-

Long-distance oil and gas transmission

-

Offshore pipeline systems

-

Petrochemical transportation

-

Structural applications in energy projects

Its balance of strength, reliability, and cost-effectiveness makes it one of the most preferred materials in the energy sector.

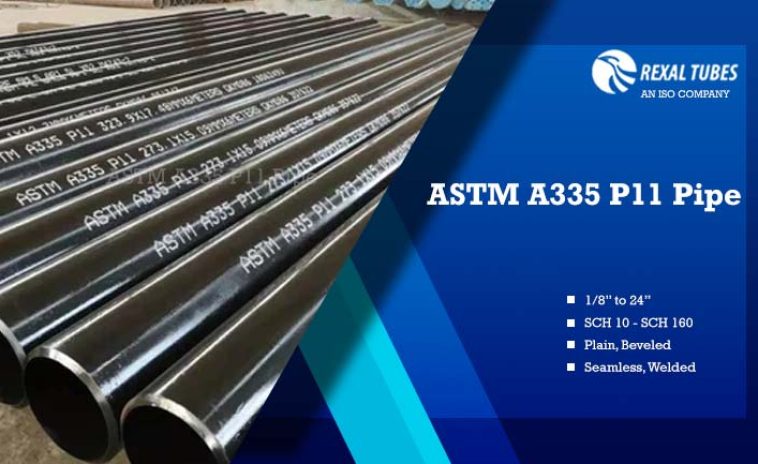

An Overview of ASTM A335 P11 Pipes

P11 pipes belong to the ASTM A335/ASME SA335 specification, which covers seamless ferritic alloy-steel pipes intended for high-temperature service. With a chromium-molybdenum (Cr-Mo) composition, P11 pipes are essential for industries that operate equipment at elevated temperatures and pressures.

Why Industries Prefer P11 Pipes

1. High Temperature Strength

P11 pipes maintain their mechanical integrity even in extreme heat, making them vital for power plants, refinery heaters, boilers, and heat exchangers.

2. Excellent Oxidation Resistance

The chromium and molybdenum content enhances the material’s ability to resist oxidation and scaling at high temperatures.

3. Long Service Life

P11 pipes offer exceptional longevity, reducing downtime and replacement costs in high-temperature industrial systems.

4. Compatibility with High-Pressure Applications

These pipes are engineered to operate under high internal pressure, making them critical for steam lines, superheater tubes, and pressure vessels.

Selecting the Right P11 Pipe Suppliers

Choosing reliable P11 pipe suppliers is crucial for ensuring the quality, efficiency, and safety of high-temperature systems. With numerous suppliers in the market, industries must consider certain factors before finalizing their vendor.

1. Quality Certifications

Authentic suppliers should adhere to ASTM, ASME, and international quality standards. Certifications such as ISO, PED, and API ensure that the supplied pipes meet global benchmarks.

2. Material Traceability

A trusted supplier provides complete material documentation, including mill test reports (MTRs), chemical composition charts, and mechanical property data.

3. Product Range and Availability

Leading P11 pipe suppliers offer a wide range of sizes, schedules, and custom requirements to support diverse industrial applications.

4. Competitive Pricing and Logistics

Reliable vendors maintain transparent pricing structures and ensure timely delivery across domestic and international destinations.

5. After-Sales Support

Technical assistance, installation guidance, and responsive customer service play a vital role in long-term project success.

API 5L X65 Pipe vs. P11: Different Needs, Common Reliability

While API 5L X65 and P11 pipes serve different functional requirements, they share significant strengths such as durability, long service life, and suitability for demanding environments.

-

API 5L X65 Pipe is ideal for transportation and pipeline systems.

-

P11 pipes, on the other hand, excel in high-temperature and high-pressure settings.

Industries often use both materials together in large-scale refinery and power plant operations, making it crucial to source these products from reputable manufacturers and suppliers.

Conclusion

Both API 5L X65 Pipe and high-quality pipes sourced from leading P11 pipe suppliers play a major role in strengthening infrastructure across energy, petrochemical, and industrial sectors. Their ability to withstand harsh conditions, combined with excellent mechanical and thermal performance, makes them indispensable in modern engineering projects. Choosing the right materials and trusted suppliers ensures greater efficiency, enhanced safety, and long-term cost savings—key factors for any successful industrial operation.