Choosing the Right Stainless Steel Supplier: SS 316 Round Bar Suppliers and SS 304 Pipe Suppliers

In the world of industrial construction, manufacturing, and fabrication, selecting the right stainless steel material is crucial for ensuring durability, corrosion resistance, and overall performance. Among the wide array of stainless steel products available, SS 316 round bars and SS 304 pipes stand out for their exceptional quality and versatility. For businesses and industries looking for reliable supply chains, connecting with trusted SS 316 round bar suppliers and SS 304 pipe suppliers is a critical step toward success.

Understanding Stainless Steel Grades

Stainless steel is known for its resistance to rust, corrosion, and staining. The two most commonly used grades are SS 304 and SS 316, each offering distinct properties suitable for specific applications.

SS 304 is the most versatile and widely used stainless steel grade. It contains approximately 18% chromium and 8% nickel, making it highly resistant to oxidation and corrosion. This grade is ideal for applications in food processing, chemical containers, water tanks, and general structural components. Its widespread availability makes it a favorite among SS 304 pipe suppliers worldwide.

SS 316, on the other hand, contains molybdenum in addition to chromium and nickel, which enhances its resistance to corrosion in chloride-rich environments such as coastal areas or chemical plants. This grade is preferred for marine equipment, chemical processing plants, and pharmaceutical industries. As a result, sourcing materials from reliable SS 316 round bar suppliers ensures that manufacturers receive high-quality products that meet stringent industrial standards.

The Importance of Reliable Stainless Steel Suppliers

When sourcing stainless steel, the choice of supplier can make a significant difference in quality, cost, and project efficiency. Reputable SS 316 round bar suppliers and SS 304 pipe suppliers provide several advantages:

-

Consistent Quality: Trusted suppliers ensure that every batch meets international standards, reducing the risk of defects and failures.

-

Wide Range of Products: Leading suppliers offer various sizes, diameters, and finishes, allowing clients to select materials that precisely match their project requirements.

-

Timely Delivery: In industries where time is critical, dependable suppliers guarantee on-time delivery, preventing production delays.

-

Expert Guidance: Experienced suppliers can provide technical advice on material selection, helping businesses choose between SS 304 and SS 316 based on specific project needs.

Applications of SS 316 Round Bars

SS 316 round bars are highly sought after due to their exceptional corrosion resistance and mechanical properties. Some of their common applications include:

-

Marine Equipment: Ideal for boat fittings, propeller shafts, and offshore structures exposed to seawater.

-

Chemical Industry: Used in chemical storage tanks, heat exchangers, and processing equipment where exposure to harsh chemicals is frequent.

-

Medical Devices: SS 316’s biocompatibility makes it suitable for surgical instruments and medical implants.

-

Food Processing Equipment: Resistant to food acids and cleaning chemicals, ensuring hygiene and durability.

By sourcing from reputable SS 316 round bar suppliers, manufacturers can ensure that the materials are produced with precise chemical composition and mechanical properties, critical for high-performance applications.

Applications of SS 304 Pipes

SS 304 pipes are widely used across industries due to their strength, durability, and resistance to oxidation. Their common applications include:

-

Water and Wastewater Systems: SS 304 pipes are resistant to corrosion, making them ideal for plumbing and water transport.

-

Construction: Structural applications such as handrails, supports, and frameworks.

-

Food and Beverage Industry: Used in pipelines and processing equipment where hygiene is essential.

-

Automotive and Chemical Industries: For exhaust systems, chemical tanks, and other critical components.

Reliable SS 304 pipe suppliers ensure that the pipes meet dimensional tolerances, surface finish requirements, and ASTM/ISO standards. This reliability helps reduce maintenance costs and enhances the lifespan of industrial installations.

Tips for Choosing Stainless Steel Suppliers

When searching for SS 316 round bar suppliers or SS 304 pipe suppliers, consider the following factors:

-

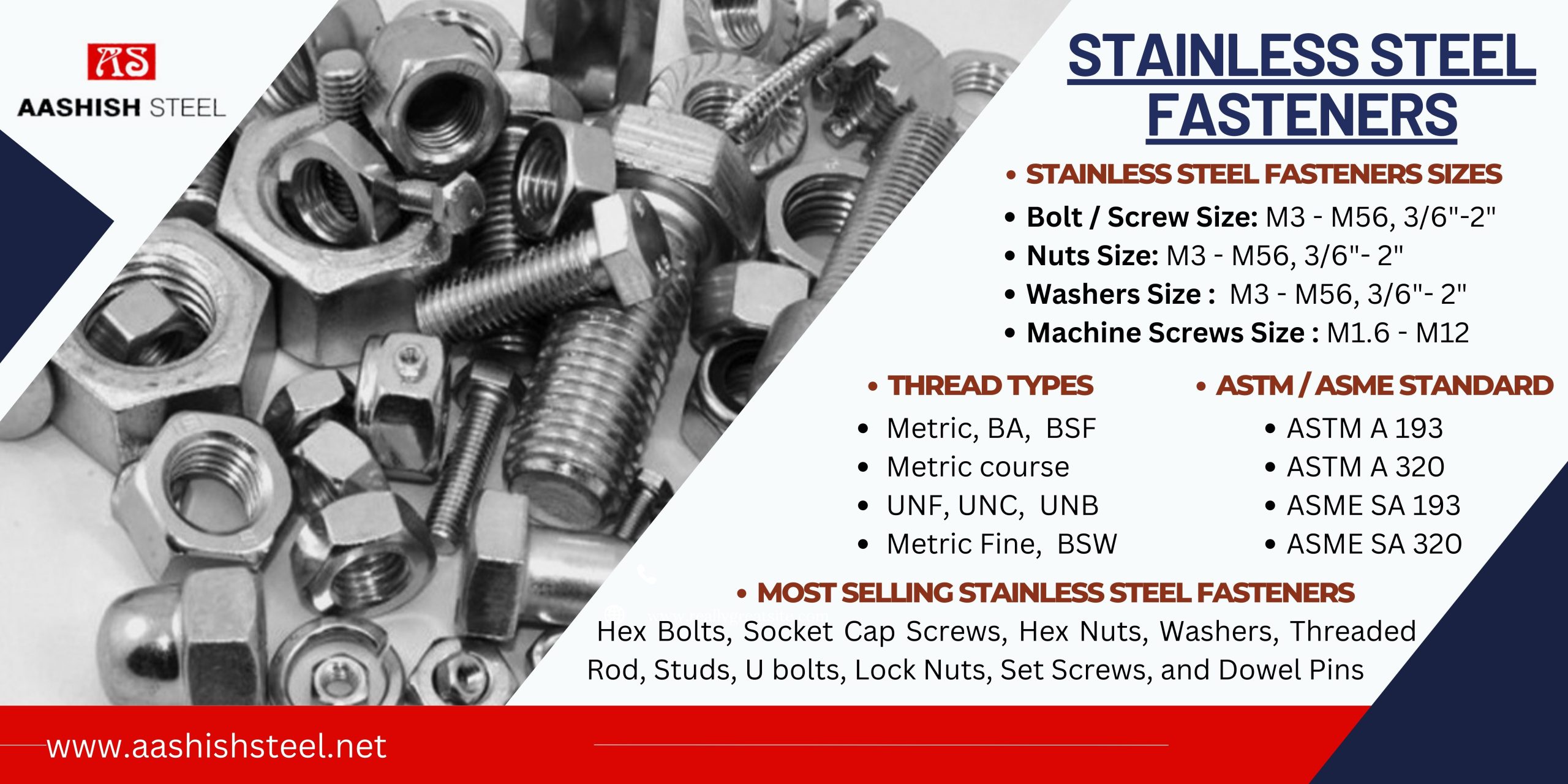

Certification and Compliance: Ensure the supplier complies with ASTM, ISO, or other relevant standards.

-

Product Range: A wide variety of sizes, shapes, and finishes indicates a well-equipped supplier.

-

Customer Support: Suppliers who offer technical guidance and after-sales support can be valuable partners.

-

Reputation and Experience: Long-standing suppliers with positive reviews provide assurance of product quality and service.

Conclusion

Selecting the right stainless steel products and suppliers is essential for achieving reliability, durability, and performance in any industrial application. SS 316 round bars offer superior corrosion resistance, making them ideal for marine and chemical applications, while SS 304 pipes provide versatile and cost-effective solutions for plumbing, food processing, and structural purposes. By partnering with trustworthy SS 316 round bar suppliers and SS 304 pipe suppliers, businesses can ensure that they receive high-quality stainless steel products tailored to their specific requirements.

Investing time in finding reliable suppliers not only safeguards the integrity of your projects but also enhances efficiency, reduces maintenance costs, and ensures long-term performance. Whether you are in construction, manufacturing, or the chemical industry, stainless steel remains a smart choice, and sourcing from the right supplier is the first step toward success.